Die Casting offers many benefits over other methods of part creation. Die casting provides an economical method of making durable parts with flexibility in design. Compare die casting to other manufacturing methods and see if metal castings are a fit for your designs.

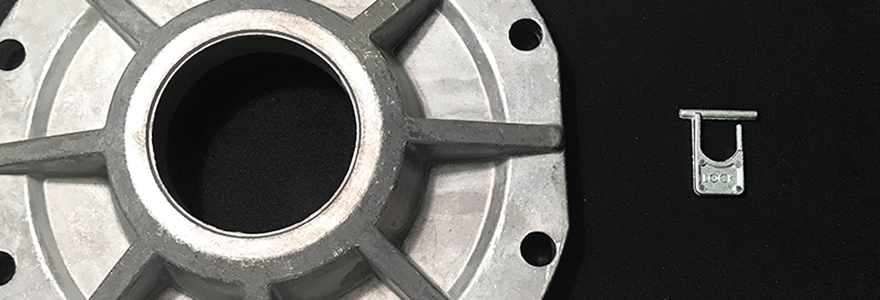

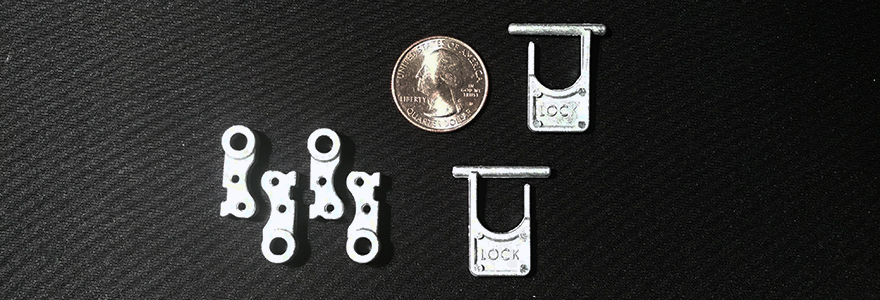

Complex Shapes - A metal casting allows for complex shapes with closer tolerances than many other processes used in mass production.

Accuracy - A metal casting gives the repeated accuracy of tight tolerances with little or no machining required.

Stability - A metal casting produces stability and strength for repetitive use while tens of thousands can be produced before any additional tooling is required.

Multiple Finishes - The metal die casts can be completed with smooth or textured surfaces, and easily plated or finished with little to no surface preparation. Powder coating adheres well to castings for a beautiful finish.

Simplifies Assembly - A metal casting can be designed to provide integral fastening elements, such as bosses and studs. Holes can be cored and made to tap sizes or external threads can be cast adding a new dimension to flexibility with assemblies.

Metal Die Casting vs Plastic Injection Molding - Die casting fabricates stronger parts that have greater stability and durability, as well as having greater resistance to extreme temperatures.

Metal Die Casting vs Sand Casting and Permanent Molding - Metal die casts produce parts with thinner walls, closer dimensional limits and smoother surfaces. Faster production in casting makes labor costs per die cast lower providing all the benefits for a fraction of the cost.

Metal Die Casting vs Forgings - Die casts in metal generates more multifaceted shapes with the ability to put up with harsh or difficult conditions, thinner fortifications, and lower finishing expenses.

Metal Die Casting vs Stampings - Die casting metal not only allows more extensive shaping with different choices in thickness, but one casting could replace several stampings. Die casts result in an exceptional cost and a real shortcut in assembly time.

Metal Die Casting vs Screw Machine Products - Shapes that are difficult or impossible to produce from bar or tubular stock make die casting a must, while maintaining exacting tolerances. Die casting also requires fewer operations and reduces scrap.

Metal Die Casting vs Machining Parts from Billets/Bar Stock - Fabricating parts from billets is a time consuming process that generates considerable amounts of scrap and generally is only used when very few parts are needed. Comparatively, many metal castings are produced in the same time it takes to machine just one part from a billet making die casts far more cost effective for large quantities.

Without a doubt, the smart money choice to improve the performance of your finished part is die casting.

1

1 2

2 3

3 4

4